Instrumentation and Control Engineering Training Course

Course Overview

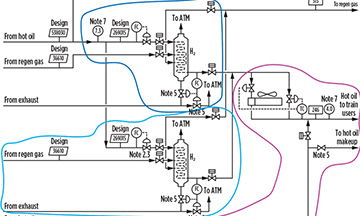

The control of processes in today’s oil, gas and chemical industries requires and needs accurate knowledge of process conditions and this, in turn, means the accurate measurement of those conditions. Without any measurement, there can be no control and no information as to the state of the process.

A greater understanding of the measuring equipment and the instruments can develop and improve the performance of the operator and this, in turn, will improve plant performance. Better knowledge of how equipment is selected, how it is constructed, how it’s work helps an operator to identify the cause of problems and prevent their recurrence.

What are the topics covered in instrumentation and control engineering course?

Some of the main topics include:

- Overview on the fundamentals and principles of Process Measurement, Instrumentation systems and Process variables. Symbols and units used and sample calculations

- Principles of operation of Sensors and Transducers used in:

- Temperature Measurement

- Strain measurement

- Pressure measurement

- Flow measurement

- Level measurement

- Ultrasonic techniques for non-invasive process measurement

- Principles of Process Control and study of the key Control strategies used, leading to an explanation of the 3-term PID controller

- Explanation and description of a method used to ‘tune’ a 3-term PID controller

This Zoe training course will empower you with the consciousness of knowing the major types of measuring control instruments and equipment that are used and the principles behind the selection, construction and operation of process measurement and control equipment.

Course Objectives

Upon completing this Instrumentation and Control Engineering course successfully, participants will be able to:

- To provide an understanding of the principles of operation of a range of sensors and transducers

- Exercise a hands-on approach, that will empower the delegate to investigate the operation of an instrumentation system through designing, building and testing typical sensor combined with appropriate signal conditioning circuits

- Familiarize and be confident with a range of measurement techniques

- Specify, indicate and design instrumentation systems for pressure, level, temperature and flow

- Identify and recognize a large number of industrial analytical measuring instruments

- Facilitate the following types of measurement: pH, conductivity, turbidity, hygrometry, dissolved oxygen, total free chlorine and on‐line chromatography

- Apply and Implement procedures for testing and calibration of analytical instruments

- Troubleshoot and identify problems with instrumentation systems

- Comprehend the concepts of Process Control and acquire the knowledge relating to the characteristics and properties of a process variable being measured

- Describe and explain the construction and operation of the most important analytical instruments

- Get acquainted and be knowledgeable in PID control and develop the ability to ‘tune’ a process control system using PID control

- Get knowledge of open and closed loop control and examples

- Get a good concept of difference between manual and automatic control

- Understand automation and steps performed by operator or the controller

- Know control actions and modes of controlIsolate control loops and detect a faulty instrument

Training Methodology

This collaborative Instrumentation and Control Engineering training program will comprise the following training methods:

- Lectures

- Seminars and Presentations

- Group Discussions

- Assignments

- Case Studies and Functional Exercises

Zoe Talent Solutions follows the ‘Do-Review-Learn-Apply’ model.

Organisational Benefits

Companies who nominate their employees to participate in this Instrumentation and Control Engineering course can benefit in the following ways:

- Keep your company one step ahead with this all-inclusive overview of Instrumentation and Control Engineering

- Assist technical committees to create, publish and revise working standards relating to Instrumentation and Control Engineering

- Cautiously study examples and case studies to illustrate the material being discussed and ensure that the material is appropriate to the organisation represented

- Leave with an awareness and understanding of their roles and responsibilities in the workplace in relation to Instrumentation and Control Engineering

Personal Benefits

Individuals who participate in this Instrumentation and Control Engineering course can gain from it in the following ways:

- Understand and know the principle of operation of a range of sensors and transducers used in the measurement of flow, temperature, pressure, strain and level

- Review and assess the construction and operation of the most important sensors and transducers and their application in process measurement systems

- Gauge and select the most appropriate sensor technology for a given instrumentation system

- Design, build and test by means of a given specification and sensor, their own instrumentation system within the course room

- Recognize and identity components and features of a Process control system

- Calibrate, adjust and signal condition the above system and take measurements from the system

- Understand the limitations of Open loop systems and be conscious of the inherent problems associated with Closed-loop negative feedback systems

- Optimise control by tuning a system with the use of a relevant software

Who Should Attend?

Instrumentation and Control Engineering training course would be suitable for:

- Electronic Engineers and Technicians

- Chemical Engineers and Technicians

- Electrical Engineers and Technicians

- Electronic Design Engineers

- Instrumentation Technicians

- Electricians

- Installation and Maintenance Technicians

- Instrument and Process Control Technicians

- Instrument Fitters

- Maintenance Engineers

- Mechanical Engineers and Technicians

- Operations Engineers

- Process Technicians

- Production Professionals

- System Integrators

- Other professions (Engineers, Technicians) involved and working in the Process Industry who require an appreciation and understanding of the techniques used in Process Measurement and Control

Course Outline

MODULE 1: Introduction and Pressure Measurement

- Sensor and transducer

- General remarks

- Absolute and relative pressure

- Measurement Units

- Bourdon Pressure Gauges

- Differential Manometers

- Weight Manometers

- Structure and Functioning

MODULE 2: Temperature Measurement

- General remarks

- Measurements Units

- Thermocouple

- Filled system

- Bimetallic element

- Thermometers

MODULE 3: Flow Measurement

- General Remarks

- Measurement Units

- Flow Meter

- Coriolis Principle

- Head Flow Meters (Venturi Tube, Orifice Plate, Dall Flow Tube, Pitot Tube, Annubar)

- Rotameters (Variable Area Flowmeter, Glass Tubes, Metal Tubes)

- Turbine Flowmeters

- Positive displacement flowmeters

- Electromagnetic Flowmeter

- Ultrasonic Flow Equipment

- Vortex flowmeters

- Calibrated Diaphragm System

- Calibrated Tank System

MODULE 4: Level Measurement

- General Remarks

- Level Indicators

- Hydrostatic Drive Meters

- Differential Pressure Gauges

- Radar level measurement

MODULE 5: Analysers

- General

- Dew Point Analyzer

- Type of moisture measurement

- O2 analyzer

- SO2 analyzer

- PH analyzer

- Corrosion meter

- Datasheets analysis

MODULE 6: Other Process Instruments

- Pressure Switches, Compact temperature switches, Level Switches Structure, Flow switches

- Position transmitters

- Pressure Relief Valve

- Solenoid Valves

MODULE 7: Execution of Electric Connection for Instruments in Dangerous Area

- General Remarks

- EExd Execution

- EExi Execution (Passive Barriers-ZENER, Galvanically isolated active barriers)

MODULE 8: The Importance of Process Control

- The importance of process control, introduction and definition of process control

- Reduce Variability, Increase Efficiency, Ensure Safety

- Control Theory Basics

- Components of Control Loops

- Types of Process Controllers

MODULE 9: Controller Algorithms and Tuning

- Controller Algorithms

- Controller’s Tuning

- Proportional Mode

- Integral Mode

- Derivative Mode

- Controller Algorithms (Proportional, PI, and PID Control)

MODULE 10: Process Control Loops

- Single Control Loops and examples

- Pressure Control Loops

- Flow Control Loops

- Level Control Loops

- Temperature Control Loops

- Multivariable Loops and examples

- Feedforward Control (Open Control Loop)

- Feedforward Plus Feedback

- Cascade Control

- Ratio Control

- Batch Control