Power Plant Operator Course

| Date | Format | Duration | Fees | |

|---|---|---|---|---|

| 06 May - 10 May, 2024 | Live Online | 5 Days | $2250 | Register |

| 24 Jun - 28 Jun, 2024 | Live Online | 5 Days | $2250 | Register |

| 15 Jul - 19 Jul, 2024 | Live Online | 5 Days | $2250 | Register |

| 23 Sep - 04 Oct, 2024 | Live Online | 10 Days | $4495 | Register |

| 25 Nov - 03 Dec, 2024 | Live Online | 7 Days | $3147 | Register |

| 09 Dec - 13 Dec, 2024 | Live Online | 5 Days | $2250 | Register |

| Date | Venue | Duration | Fees | |

|---|---|---|---|---|

| 13 May - 17 May, 2024 | Dubai | 5 Days | $4750 | Register |

| 27 May - 31 May, 2024 | Dar Es Salam | 5 Days | $4950 | Register |

| 10 Jun - 14 Jun, 2024 | Istanbul | 5 Days | $5695 | Register |

| 10 Jun - 14 Jun, 2024 | Dubai | 5 Days | $4750 | Register |

| 01 Jul - 05 Jul, 2024 | Toronto | 5 Days | $5695 | Register |

| 15 Jul - 19 Jul, 2024 | Dubai | 5 Days | $4750 | Register |

| 12 Aug - 16 Aug, 2024 | Dubai | 5 Days | $4750 | Register |

| 09 Sep - 20 Sep, 2024 | Amsterdam | 10 Days | $9850 | Register |

| 30 Sep - 04 Oct, 2024 | Dubai | 5 Days | $4750 | Register |

| 21 Oct - 25 Oct, 2024 | Dubai | 5 Days | $4750 | Register |

| 11 Nov - 22 Nov, 2024 | Lagos | 10 Days | $9150 | Register |

| 18 Nov - 22 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 16 Dec - 20 Dec, 2024 | Dubai | 5 Days | $4750 | Register |

| 23 Dec - 27 Dec, 2024 | Accra | 5 Days | $4950 | Register |

Course Overview

A power plant is an engineering facility used to produce electric power with the support of one or more generators, which transforms energy from different sources into electric power. Power plant operators regulate and supervise boilers, turbines, generators, and any auxiliary apparatus in power-generating plants.

These operators also distribute power demands among multiple generators, merge power from generators, and monitor devices to maintain the voltage and regulate the electricity which flows from the plant.

This training course offers an insight into the basic principles, as well as selected in-depth knowledge, regarding the operation, control, construction, fabrication, and composition of the most popular types of fossil-fuelled power plants like thermal, gas, and diesel power stations.

The program also provides an insight into the concepts and theories of electrical and mechanical engineering, electrical machines and electrical drives, thermodynamics, etc. to further the participants’ knowledge in the domain.

Not only does this training course deliver a supreme understanding of the power station control variables, and instrumentation techniques, but it also discusses the methods of monitoring and control of the processes and the operation of control devices, valves, sensors, actuators, heat exchangers, compressors, and so on.

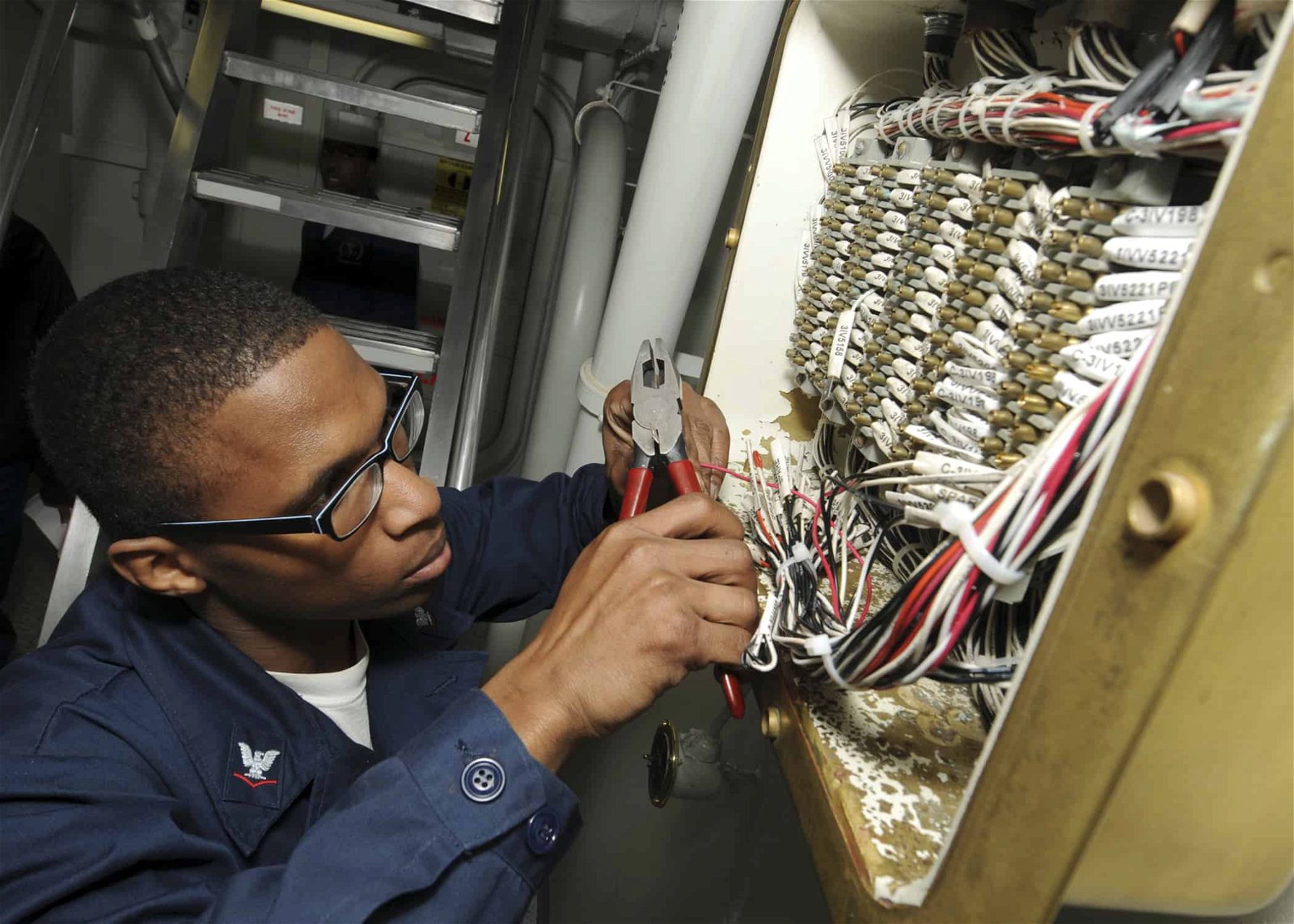

This is important because power plants and transmission stations have particularly high risk, and workers should be prepared to work in such hazardous environments. When operators perform their tasks either inside or outside the control room, they may be subjected to danger from electric shocks, falls, or burns. Therefore, it is important to be aware of the procedures to be followed to prevent such accidents.

What areas does this “Certified Power Plant Operator” course cover? This program will delve into topics like types of power plants and their unique features; power generation theory; industrial power plants, processes, and control procedures; the operation and selection criteria for power plants; thermal, gas, and diesel generation; and the fundamentals of electric machines, and control devices.

This Zoe training course will empower you with a detailed understanding of the various aspects of operating power plants in an educated manner, thereby reducing the risk of errors caused due to a lack of knowledge and awareness in the domain.

Course Objectives

Upon completing this Certified Power Plant Operator course successfully, participants will be able to:

- Learn basic engineering principles associated with power plants

- Grasp the operation of power plants

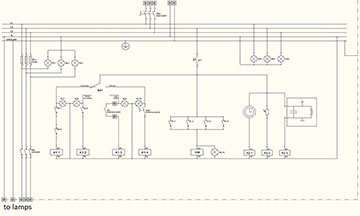

- Analyse power-related processes and control diagrams

- Learn about the different features of the power plant, selection criteria and optimisation techniques

- Get acquainted with the maintenance protocols, troubleshooting procedures, and control operations of power plants

- Comprehend the power plant parameters, disturbances, and control techniques

Training Methodology

This collaborative Certified Power Plant Operator training program will comprise the following training methods:

- Lectures

- Seminars & Presentations

- Video Clips

- Group Discussions

- Assignments

- Case Studies & Functional Exercises

Just like all our acclaimed courses, this program also follows the ‘Do-Review-Learn-Apply’ model.

Organisational Benefits

Companies who nominate their employees to participate in this Certified Power Plant Operator course can benefit in the following ways:

- Keep your company one step ahead with this all-inclusive overview of power plant operation

- Assist technical committees to create, publish and revise working standards relating to the power plant operation

- Carefully study examples and case studies to illustrate the material being discussed and ensure that the material is appropriate to the organisation represented

- Leave with an awareness and understanding of their roles and responsibilities in the workplace in relation to power plant operation

Personal Benefits

Individuals who participate in this Certified Power Plant Operator course can gain from it in the following ways:

- Keep up with late-breaking developments in power plant operation by studying new literature and other sources of information

- Benefit from a tailor-made academic program for technicians or equivalent workforce involved in power plant operation

- Get yourself trained, assessed, and certified by experts in the power plant operation domain

- Provide examples of issues that they encounter during their normal working activities and possible solutions

Who Should Attend?

This Certified Power Plant Operator course would be suitable for:

- Project engineers and project managers

- Power station maintenance crew

- Power station operators, technicians, engineers, and managers

- Electrical engineers and mechanical engineers of different competency levels

- University graduates, site engineers and technical crew

- Professionals in related occupations like diesel engine specialists, computer-controlled machine tool operators, stationary engineers and boiler operators, gas plant operators, petroleum pump system operators, refinery operators, and gas pumping station operators

Course Outline

MODULE 1: FUNDAMENTALS OF MECHANICAL & ELECTRICAL ENGINEERING

- Sensors, actuators

- Pumps, compressors, turbines, fan, blowers

- Pneumatics and hydraulics

- Control valves and cylinders, electrical actuation

- Theory of heat transfer

- Electric generators, motors, and drives

MODULE 2: GAS POWER STATION

- Overview of gas power stations

- Fundamentals and thermodynamics

- Gas turbine components

- Construction, lubrication system, fuel system, and auxiliary systems

- Protection, control, and instrumentation

- Installation, operation, and maintenance

MODULE 3: THERMAL POWER STATION

- Overview of thermal power stations

- Fuel combustion and steam generation process

- Boiler auxiliary plant, operation, and controls

- Boilers and power generation

- Waste heat recovery

- Boiler emission control, maintenance, and troubleshooting

MODULE 4: DIESEL GENERATOR POWER STATION

- Power plant types and components, engine types

- Engine technology and classifications

- DG types, protection, insulation, earthing and construction

- DG set assemblies & components

- DG plant layout

- DG operation and maintenance

MODULE 5: PROCESS INSTRUMENTATION & CONTROL

- Process control fundamentals

- Measurement and control of pressure, level, flow, and heat

- Electronic controllers

- Process flow diagram (PFD), P&ID, transfer function

- Open & closed-loop controllers

- Operational amplifiers, analogue & digital controllers

MODULE 6: MANAGEMENT AND ORGANISATION OF PLANT OPERATIONS

- Functions and tasks of plant operations

- Operating policy

- Human resources and qualification of personnel

- Performance objectives and standards

- Interfaces with other plant groups

MODULE 7: SHIFT COMPLEMENT AND FUNCTION

- Shift supervisor

- Operators

- Shift safety engineer or technical adviser

- Shift technical support personnel

MODULE 8: SHIFT ROUTINES AND OPERATING PRACTICES

- Shift arrangements

- Shift operations

- Shift turnover

- Availability and use of operating procedures

- Pre-job briefings

- Conduct in the control room

- Shift rounds

- Communications

- Shift records and log keeping