Electrical Safety Procedures and Standards for Electrical Engineers

| Date | Venue | Duration | Fees | |

|---|---|---|---|---|

| 05 May - 09 May, 2024 | Muscat | 5 Days | $4950 | Register |

| 27 May - 31 May, 2024 | Dubai | 5 Days | $4750 | Register |

| 17 Jun - 28 Jun, 2024 | Dubai | 10 Days | $8775 | Register |

| 08 Jul - 12 Jul, 2024 | Dubai | 5 Days | $4750 | Register |

| 12 Aug - 16 Aug, 2024 | Dubai | 5 Days | $4750 | Register |

| 19 Aug - 30 Aug, 2024 | New York | 10 Days | $9850 | Register |

| 16 Sep - 20 Sep, 2024 | Prague | 5 Days | $5695 | Register |

| 16 Sep - 20 Sep, 2024 | Dubai | 5 Days | $4750 | Register |

| 07 Oct - 18 Oct, 2024 | New Delhi | 10 Days | $9375 | Register |

| 28 Oct - 01 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 04 Nov - 08 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 09 Dec - 13 Dec, 2024 | Dubai | 5 Days | $4750 | Register |

| 23 Dec - 27 Dec, 2024 | Dar Es Salam | 5 Days | $4950 | Register |

Course Overview

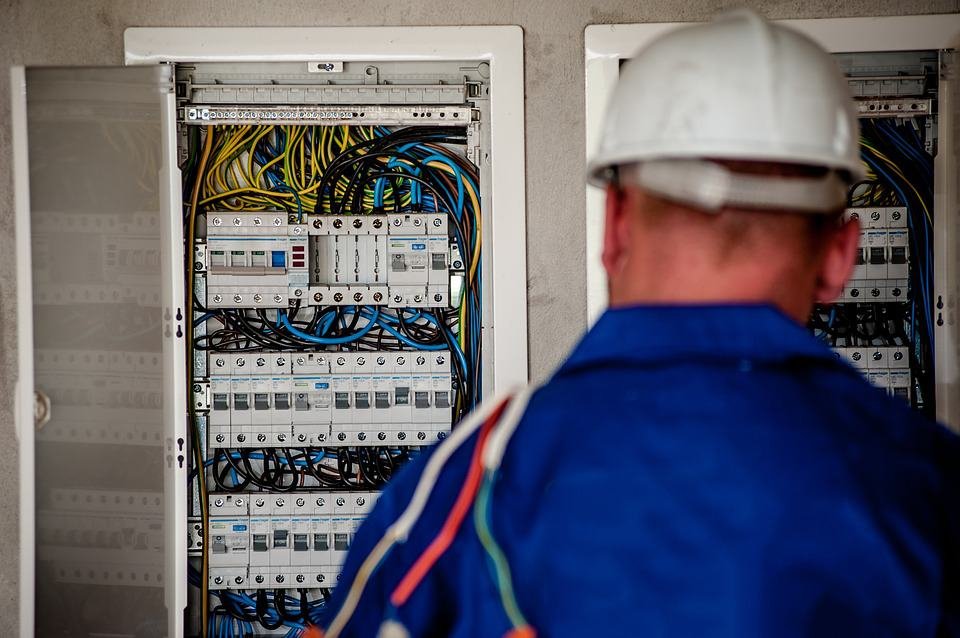

Electricity is essential to modern life, both at home and at work. Workers like electricians, electronic workers, and power line workers work with electricity directly. Safe design, safe installation and the safe operation of industrial electrical equipment are key components that formulate high standards of electrical engineering safety.

Many people work around electricity but are not qualified to directly handle electrical components, or in other words, not permitted to be possibly exposed to live electrical parts.

Why is this “Electrical Safety Procedures and Standards for Electrical Engineers” course integral to anyone who works in the power and energy industries? Electrical injuries are known to be the fifth most common source of occupational fatalities and these injuries can be reduced if the right preventive practices are in place.

The best way for anyone who works with electrical safety training to avert injury to themselves or others, as well as any harm to property, is to practice verified electrical safety protocols. Electrical safety programs in the workplace not only reduce the frequency of injury but also protect companies and their employees from the financial consequences of a work-related mishap.

This Zoe training course will empower you with comprehensive information on the detection and prevention of injuries due to electrical hazards.

Course Objectives

Upon completing this Electrical Safety Procedures and Standards for Electrical Engineers course successfully, participants will be able to:

- Promote electrical safety in office environments

- Reduce the occurrence of electric shock injuries, flash/radiation burns and electrocution

- Lessen the injuries caused from failure to stop or operate, and unintended operation of equipment that is electrically powered

- Avoid surface temperatures and electrical arcing from causing an electrical hazard

- Provide electrical safety technology with monitoring controls that help prevent non-electrical hazards

- Prevent fires caused by the malfunction of electrical equipment

Training Methodology

This collaborative Electrical Safety Procedures and Standards for Electrical Engineers training program will comprise the following training methods:

- Lectures

- Seminars & Presentations

- Group Discussions

- Assignments

- Case Studies & Functional Exercises

Similar to all our courses, this program also follows the ‘Do-Review-Learn-Apply’ model.

Organisational Benefits

Companies who nominate their employees to participate in this Electrical Safety Procedures and Standards for Electrical Engineers course can benefit in the following ways:

- Keep your company one step ahead with this all-inclusive overview of electrical safety procedures and standards

- Ensure safe operation of the electrical equipment and installations in your workplace

- Assist technical committees and boards to create, publish and update working standards pertaining to electrical safety procedures and standards

- Support the relevant authorities in writing, editing, and processing standards for electrical safety procedures and standards

- Establish discussions with related government organisations regarding regulations that affect electrical engineering safety and the government’s respective standards

Personal Benefits

Individuals who participate in this Electrical Safety Procedures and Standards for Electrical Engineers course can gain from it in the following ways:

- Keep up with late-breaking developments in electrical safety procedures and standards by studying new literature and other sources of information

- Benefit from a tailor-made academic program for technicians or equivalent workforce involved in electrical safety procedures and standards

- Get yourself trained, assessed, and certified by experts in the electrical safety procedures and standards domain

- Identify, act on, and report any issues with electrical safety procedures and standards

- Perform the test activities and site procedures related to electrical safety procedures and standards

- Detect and utilise the appropriate PPE tools and methods when carrying out tasks to ensure compliance with electrical safety procedures and standards

- Enhance your skills and get yourself trained for further qualifications in the field of electrical safety procedures and standards

Who Should Attend?

This Electrical Safety Procedures and Standards for Electrical Engineers course would be suitable for:

- Electricians

- Builders and building workers

- Communications engineers

- Electricity and energy providers and engineers

- Appliance repair workers

- Cable engineers

- Electrical supervisors

- Electrical managers

Course Outline

MODULE 1: INTRODUCTION TO SAFE WORKING CULTURES

- How to evaluate existing safety controls

- The importance of culture and mindset in maintaining safe work practices

- Best management practices

- Housekeeping

- Employee orientation and onboarding

MODULE 2: TESTING SAFETY PRACTICES

- Testing for chemicals

- Performing job hazards assessments

- The proper use of personal protective equipment (PPE) in safety procedures

- First aid and resuscitation

- Fire prevention and protection

- Safely working in excavations and other confined spaces

MODULE 3: GENERAL REQUIREMENTS FOR WORK PRACTICES

- Identify the training requirements

- Evaluate types of training and documentation procedures required

- Discuss the fundamentals of developing an electrical safety program

- Weigh the potential risks of working with electrical hazards

- Demonstrate how to use test equipment and instruments safely

MODULE 4: ESTABLISHING AN ELECTRICALLY SAFE WORK CONDITION

- Describe the different forms of control procedures

- Define the requirements for lockout/tagout devices

- Identify the procedures of releasing lockout/tagout devices

- Understand the requirements for temporary grounding equipment

MODULE 5: TESTING SAFE USE OF VARIOUS FIELD EQUIPMENT

- Hand tools and workshop tools and machinery

- Ladder and scaffolding safety

- Forklift safety

- Crane operation

- Work platforms

- Safely working with compressed gas cylinders

- Drum handling safety

- Safe welding practices

MODULE 6: WORK INVOLVING ELECTRICAL HAZARDS

- Recognise electrical hazards and know when it is justifiable to work near such hazards

- Understand the purpose and use of energised electrical work permits

- Determine shock hazards associated with approach boundaries

- Determine required arc flash protection

- Analyse insulated tools and other protective equipment

- Identify alerting techniques

- Study the safety procedures for overhead lines

MODULE 7: SAFETY-RELATED MAINTENANCE REQUIREMENTS

- General maintenance of electrical equipment

- Identify safety-related maintenance practices

- Describe the electrical maintenance requirements for facilities

- Determine specific maintenance of fuses and circuit breakers

- Recognise the criticality of maintaining equipment in hazardous locations

MODULE 8: SAFETY REQUIREMENTS FOR SPECIAL EQUIPMENT

- Understand the dangers of working with special electrical equipment

- Determine the safety requirements for special equipment

- Identify safe work practices for electrolytic cells

- Recognise safe work routines for installing and maintaining batteries

- Classify safe work procedures for lasers

- Categorise safe work practices for power electronic equipment

- Identify safe work procedures for laboratories