Risk Based Inspection (RBI) Procedure and Methodology Training

| Date | Format | Duration | Fees | |

|---|---|---|---|---|

| 13 May - 17 May, 2024 | Live Online | 5 Days | $2250 | Register |

| 24 Jun - 28 Jun, 2024 | Live Online | 5 Days | $2250 | Register |

| 21 Jul - 25 Jul, 2024 | Live Online | 5 Days | $2250 | Register |

| 16 Sep - 20 Sep, 2024 | Live Online | 5 Days | $2250 | Register |

| 04 Nov - 08 Nov, 2024 | Live Online | 5 Days | $2250 | Register |

| 23 Dec - 27 Dec, 2024 | Live Online | 5 Days | $2250 | Register |

| Date | Venue | Duration | Fees | |

|---|---|---|---|---|

| 29 Apr - 03 May, 2024 | Kampala | 5 Days | $4950 | Register |

| 13 May - 17 May, 2024 | Dubai | 5 Days | $4750 | Register |

| 10 Jun - 14 Jun, 2024 | New York | 5 Days | $5695 | Register |

| 24 Jun - 28 Jun, 2024 | Dubai | 5 Days | $4750 | Register |

| 07 Jul - 11 Jul, 2024 | Jeddah | 5 Days | $4950 | Register |

| 29 Jul - 02 Aug, 2024 | Dubai | 5 Days | $4750 | Register |

| 05 Aug - 09 Aug, 2024 | Dubai | 5 Days | $4750 | Register |

| 02 Sep - 06 Sep, 2024 | Paris | 5 Days | $5695 | Register |

| 16 Sep - 20 Sep, 2024 | Dubai | 5 Days | $4750 | Register |

| 07 Oct - 11 Oct, 2024 | Dubai | 5 Days | $4750 | Register |

| 04 Nov - 08 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 18 Nov - 22 Nov, 2024 | Prague | 5 Days | $5695 | Register |

| 09 Dec - 13 Dec, 2024 | Paris | 5 Days | $5695 | Register |

| 09 Dec - 13 Dec, 2024 | Dubai | 5 Days | $4750 | Register |

Course Overview

What is RBI methodology?

Oil, gas and chemical industries’ installations are increasingly becoming complex and large globally. They have great economic values. Stakeholders are globally interdependent on their smooth functioning. Their health (integrity) must be sustained using Risk Based Inspection (RBI) and Condition Monitoring (CM). If equipment and piping of these installations fail in operation, they not only have production and economic loss but also serious incidents having adverse Health, Safety and Environmental (HSE) consequences. Depending upon stakes and risks involved, the concerned industry must pay due attention to RBI and the associated procedures and methodology.

How are risk-based inspections implemented?

RBI should be preceded by baseline (initial) inspection to record where equipment and piping originally stand with regards to their original condition (health). Subsequent RBI’s record how their health conditions are maintaining or deteriorating and help the engineers to plan the timely replacements to avert disastrous failures while in operation.

This Zoe training course will empower attendees with comprehensive knowledge of the need and procedures for Certification in Risk Based Inspection (RBI): Procedure & Methodology.

Course Objectives

This comprehensive certification course will equip the participants to:

- Learn fundamentals of Risk

- Comprehend Risk Assessment Matrix and Risk Based Inspection

- Underline RBI/Asset Integrity Management as an important element of Process Safety Management (PSM)

- Learn types, procedures, methodology and details of various inspections

- Understand Inspection of Static equipment and piping

- Appreciate Condition monitoring of rotating equipment

- Learn Non-Destructive Testing (NDT)

- Note relationship between inspection and Predictive/Preventive Maintenance

- Comprehend the importance of inspection recommendation Close-out

- Cascade lessons learnt from the inspection results into design documents

- Understand and address Insurance, Legal and Statutory aspects of inspection

- Learn Management’s Maintenance Strategy and its relationship with RBI

Training Methodology

This collaborative ‘Risk Based Inspection (RBI): Procedure & Methodology’ training program will comprise the following training methods:

- Lectures (Tutor-assisted online and classroom as per prevailing situations/requirements)

- Seminars & Presentations

- Group Discussions

- Assignments

- Case Studies & Functional Exercises

Similar to all Zoe training courses, this certification also observes the ‘Do-Review-Learn-Apply’ model, for the benefit of our learners.

Organisational Benefits

Companies who nominate their employees to participate in this ‘Risk Based Inspection (RBI): Procedure & Methodology’ course can benefit in the following ways:

- Minimize adverse impact on business continuity by preventing the live failure incidents through implementation of recommended actions from the inspections.

- Reduce greatly the costs associated with failure incidents such as insurance premiums, compensation to employees, legal fees and regulatory/statutory penalties

- The culture of RBI leaves a positive impact on customers, lenders, insurance underwriters, management system certification agencies, regulatory & statutory authorities, industry and societal spectrum at large.

Personal Benefits

Individuals who participate in this ‘Risk Based Inspection (RBI): Procedure & Methodology’ course can gain from it in the following ways:

- Development of confidence by practicing techniques, procedures and methods involving RBI, and thus proving to be a successful professional.

- Since interrelationship between Inspection/Asset Integrity Management and HSE excellence is seen as an important aspect in Process Safety Management (PSM), this course will help develop a very important aspect in their professional journey which will eventually benefit whichever company they would work for.

- An individual develops an PSM attitude towards his professional, personal, family and social life with knowledge gained in this training course.

Who Should Attend?

This ‘Risk Based Inspection (RBI): Procedure & Methodology’ course would be suitable for:

- Engineering/Technical Design professionals at all levels (trainees, interns, technicians, officers, managers and others)

- All steady state line-functions at all levels – trainees, interns, officers, and managers

- Senior managers in operation, maintenance, inspection, engineering, and other line disciplines

- Middle Management and Senior Management (a smaller customized part of this course)

- Non-line functions such as office managers.

Course Outline

Module 1: Fundamental of Risk and Risk Assessment Matrix

- Concept of Risk

- Risk Assessment Matrix (RAM)

- Risk Based Inspection (RBI)

- Why Risk Based Inspection?

- RBI/Asset Integrity Management | An element of Process Safety Management (PSM)

- How small failures turn into major disruptions and incidents!

- Group discussions and assessment

Module 2: Types of Various Inspections and Reporting

- Base line (Initial) inspection

- Subsequent Risk Based Inspections

- Inspection Reporting procedure: Informal and formal/ Immediate and Routine

- Preparation of Inspection Statistics

- Presentation to the Management Information System (MIS)

- Internal and external Inspection Reports

Module 3: Procedures, Methodology and Details of Various Inspections-1

- Inspection of Static equipment and piping (Online/Live and offline/shutdown)

- API/ASME Standards of inspection of pressure vessels

- API/ASME Standards of inspection of Piping

- Visual Inspections

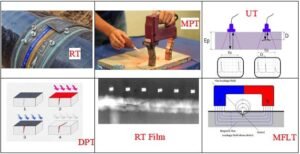

- Non-Destructive Examinations: DPT, MPT, ECT, MPT, RT, MFL, Metallography, AE etc

- Pressure/Pneumatic Testing

Module 4: Procedures, Methodology and Details of Various Inspections-2

- Inspection of Rotating equipment

- Vibration Analysis

- Vibration probes and instruments

- Online Orbit Analysis

- Bearing Analysis

Module 5: Miscellaneous Inspections – Electrical

- Electrical equipment Inspection.

- Transformers

- Oil Analysis

- Zone compatibility.

- Explosion-proof testing

- Intrinsic safety

- Insulation Tests

Module 6: Miscellaneous Inspections – Instrument and Control Equipment

- Visual Inspection of instrument and control equipment

- Functional Inspection of instrument and control equipment

- Safety Instruments System Inspections. Probability of Failure on Demand. Proof tests

- Zone compatibility

- Intrinsic safety

- Insulation Tests

Module 7: Miscellaneous Inspections – Civil/Structural

- Inspection for structural integrity

- Aging

- Seismic compatibility

- Wind compatibility

- Temperature compatibility

- Corrosion Compatibility

- Fatigue Compatibility

Module 8: Best Inspection Practices

- Publication of Loss of Containment Incidents

- Inspection, Testing & Maintenance of Safety Critical Equipment e.g., F&G Detection System, Active and Passive Fire Protection System, Relieve Systems, Safety instrumented Systems etc

- Predictive and Preventive maintenance. Don’t wait for breakdown.

- Management Review on actions

- Record results in analysis-enabled and data retrievable software

- Trend the deterioration. Where applicable, find remainder life

- Dispersion effect study. Consequence Analysis

- Plan repair or replacement

Module 9: Incidents from Live Equipment Failures

- Failure incidents having roots in poor design

- Failure incidents having roots in poor inspection, maintenance, and operation practices

- Failure analysis such as RCA, FMEA, Bowtie, Taproot, top-set etc

- Training & Continuous Professional Development

Module 10: Miscellaneous

- Importance of inspection recommendation Close-out

- Cascade lessons learnt from the inspection results into design documents

- Understand and address Insurance, Legal and Statutory aspects of inspection

- Review disastrous consequences from ignorance of RBI

- Management’s Maintenance Strategy and its relationship with RBI

- Management Commitment and Responsibility.

- Mutual Respect between Blue and White-collar functions