Flange Management and Tightening Course

| Date | Venue | Duration | Fees | |

|---|---|---|---|---|

| 29 Apr - 03 May, 2024 | Dubai | 5 Days | $4750 | Register |

| 27 May - 31 May, 2024 | Dubai | 5 Days | $4750 | Register |

| 02 Jun - 06 Jun, 2024 | Riyadh | 5 Days | $4950 | Register |

| 03 Jun - 07 Jun, 2024 | Dubai | 5 Days | $4750 | Register |

| 22 Jul - 26 Jul, 2024 | Istanbul | 5 Days | $5695 | Register |

| 22 Jul - 26 Jul, 2024 | Dubai | 5 Days | $4750 | Register |

| 26 Aug - 13 Sep, 2024 | Dubai | 15 Days | $12525 | Register |

| 16 Sep - 20 Sep, 2024 | Dubai | 5 Days | $4750 | Register |

| 14 Oct - 18 Oct, 2024 | Dubai | 5 Days | $4750 | Register |

| 21 Oct - 25 Oct, 2024 | Budapest | 5 Days | $5695 | Register |

| 17 Nov - 21 Nov, 2024 | Doha | 5 Days | $4950 | Register |

| 25 Nov - 29 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 02 Dec - 06 Dec, 2024 | Dubai | 5 Days | $4750 | Register |

Course Overview

Flanges are very important parts of piping system in oil, gas and process industries. They provide flexibility to break the continuously running very long pipe lengths to insert fittings such as valves of various types (isolation, control, non-return, safety etc), instruments (flow, analysers etc), spectacle blinds, etc. Pipe flanges also allow convenient routing of pipes. Flanges are welded at both the ends of a pipe length, a valve and other fittings.

What is flange management?

Flanges help divide the whole length of pipes in smaller parts which facilitate their removals for easy inspection and maintenance. This includes their replacements for the reasons of corrosion or other types of failures/deterioration. While flanges facilitate the above aspects, they also become pain points as they are potential leak sources in high-risk process industry, e.g. oil, gas and Petro-chemicals etc which contain flammable, explosive and toxic fluids. So, the flanges of the mating pipes and fittings must perfectly match each other at the joints. This will arrest the leakage from their joints.

‘Flange Management and Tightening’ needs special attention by those who are in the hazardous process industry.

Why is flange management important?

Since leakage of fluids in large process industries has huge national and global economic implications, this course on ‘Flange Management and Tightening’ is very important. Only trained personnel must be asked to interface ‘Flange Management and Tightening’.

This Zoe training course will empower attendees with comprehensive knowledge about ‘Flange Management and Tightening’.

Course Objectives

This comprehensive course will equip the participants to:

- Understand features of a flange and types of flanges

- Appreciate the advantages and disadvantages of flanges in oil, gas and petroleum industry.

- Learn about types of gaskets used as sandwiched layer between flanges for sealing

- Appreciate the importance of bolts and nuts and materials of construction

- Understand concepts around torque and optimum torque, as applied to flange tightening

- Management around flange tightening

- Comprehend flange bolt-tightening procedure

- Study various serious incidents due to leaking flanges in gas and petroleum industry.

- Understand care of flanges and gaskets.

- Learn about some special tools and equipment used in flange tightening

- Note the causes of corrosion and failure in flanges

- Heed the instructions by package suppliers / vendors on tightening the flanges in their equipment/packages

- Learn about some specialized agencies who carry out specialised flange tightening

- Be aware of further advanced training and certification avenues available for Flange Management and Tightening Course

Training Methodology

This collaborative ‘Flange Management and Tightening’ training program will comprise the following training methods:

- Lectures (Tutor-assisted online and classroom as per prevailing situations/requirements)

- Seminars & Presentations

- Group Discussions and workshops

- Assignments

- Case Studies & Functional Exercises

Like all Zoe training programs, the Flange Management and Tightening Course observes the ‘Do-Review-Learn-Apply’ model.

Organisational Benefits

Companies who nominate their employees to participate in this ‘Flange Management and Tightening’ course can benefit in the following ways:

- Simple but crucial knowledge on the subject

- Ensure a trouble-free and incident-free execution of flange tightening and untightening procedures

- Huge cost advantages due to money saved by not letting leakages happen and thus avoiding production interruption

- Enablement of the organization for efficient management of flanges during turnarounds while opening vessels, equipment and piping and during boxing up for starting up

Personal Benefits

Individuals who participate in this ‘Flange Management and Tightening’ course can gain from it in the following ways:

- Gain general and specialized knowledge of and skills in Flange Management and Tightening

- Have a sense of satisfaction by helping their organization by being able to carry out this crucial, regular and large operation around Flange Management and Tightening

- Enhance their career prospects with this competence and skill gained

- Learn corelation between safety and Flange Management and Tightening

- Understand specialized flanges and tools/equipment around flange management

- Learn about failure modes of flanges and ways to avoid such premature failures

- Join specialized agencies providing specialized ‘Flange Management and Tightening

Who Should Attend?

This ‘Flange Management and Tightening’ course would be suitable for:

- Maintenance, Operation, Inspection, Planning, Engineering and Fire & Safety personnel at all levels, including trainees/interns

- Insurance, Regulatory and lending agencies

- An introductory version for support staff such as Procurement and materials warehouse to help them understand care involved for flanges, gaskets and their tightening/untightening tools

Course Outline

Module 1: Concepts

- Flange and types of flanges

- Materials of construction of flanges

- Advantages and disadvantages of flanges in oil, gas and petroleum industry

- Learn about types of gaskets and their materials of construction

- Appreciate the importance of bolts and nuts and their materials of construction

- Understand what a torque and optimum torque is as applied to flange tightening

Module 2: Flange Management Requirement and Procedure

- Flange general requirements

- Bolting

- Thread lubricants and preservatives

- Flange Faces

- Requirements around gaskets for flange-joint integrity

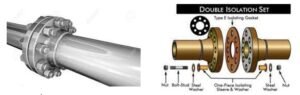

- Insulation gasket sets and specialty gaskets

Module 3: Tightening

- Tightening methods.

- Hot bolting and preventative bolting.

- Hot bolting requirements

Hot bolting procedure

- Instructions by package suppliers / vendors

- Insulation management for cryogenic and hot services flanges

Module 4: Flange Opening

- Flange joints disturbance procedure

- Insulation removals from cryogenic and hot services flanges

- Breaking flange joints

- Making joints.

- Tagging procedure.

Module 5: Maintenance Management

- Inspection & testing

- Causes of corrosion and failures in flanges

- Preventative maintenance bolting

- Preventative maintenance bolting procedure

- Flange system records

- Understand care of flanges and gaskets.

- Responsibilities

Module 6: Tools, Equipment and Manpower

- High-pressure High-force equipment including accessories

- Manual/ hand torque wrench

- Hand tools

- Manpower – Engineer, Supervisor, Safety man, Mechanic/helper

- Specialized agencies

- Precautions on storage of flanges, their tightening equipment and manpower

Module 7: Serious Incidents During Flange Bolting and Unbolting

- Safety Precautions

- Study of incidents

- Analysis of problem areas around flanges, root cause analysis and corrective actions

- Presentation of solutions by the participants

Module 8: Miscellaneous Knowledge

- Solving the associated case studies’ problems

- Specialized agencies who carry out flange bolting and unbolting

- Advanced training and certification avenues available for flange bolting and unbolting

- Reference Documentation

- Manufacturing codes and practices

- Other best practices