P&ID Training Course

| Date | Venue | Duration | Fees | |

|---|---|---|---|---|

| 29 May - 31 May, 2024 | Dubai | 3 Days | $3950 | Register |

| 03 Jun - 07 Jun, 2024 | Dubai | 5 Days | $4750 | Register |

| 07 Jul - 11 Jul, 2024 | Riyadh | 5 Days | $4950 | Register |

| 22 Jul - 26 Jul, 2024 | Dubai | 5 Days | $4750 | Register |

| 12 Aug - 16 Aug, 2024 | Kuala Lumpur | 5 Days | $5350 | Register |

| 12 Aug - 16 Aug, 2024 | Dubai | 5 Days | $4750 | Register |

| 09 Sep - 13 Sep, 2024 | Dubai | 5 Days | $4750 | Register |

| 28 Oct - 30 Oct, 2024 | Dar Es Salam | 3 Days | $4100 | Register |

| 28 Oct - 01 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 18 Nov - 22 Nov, 2024 | Dubai | 5 Days | $4750 | Register |

| 01 Dec - 12 Dec, 2024 | Doha | 10 Days | $9150 | Register |

| 02 Dec - 06 Dec, 2024 | Dubai | 5 Days | $4750 | Register |

Course Overview

This course focuses on empowering participants to get a thorough knowledge and understanding of how the plant works which will greatly enhance their ability to maintain & enhance the operation of the plant. Using the documentation provided, the workshop will help participants to know how to diagnose problems and suggest solutions on a plant that they have never seen.

Too frequently plant modifications that are instituted fix the symptom instead of the underlying problem, this workshop explains why it is so important to keep looking at the plant completely so as to solve the problem.

Participants will discover how to make documentation using simple standards and specifications as well as custom design a solution for their own plant. This training will build the consciousness that a technical person’s greatest resource is not his toolbox, but rather his drawing office and plant documentation.

As-built plant documentation is at finest 90% accurate on delivery and handover, from this point it degrades rapidly to 50 to 75% accuracy in two years, whereafter it continues a more gradual decline. This drop can be ascribed to a variety of factors.

This course will address these difficulties and show participants how to overcome them. Areas and disciplines that are covered in this course include Process, Electrical, and Instrumentation and numerous practical sessions allow the application of knowledge gained to reinforce the principles.

How do I learn P&ID? This training course from Zoe Talent Solutions introduces the participants to the drawings, specifications, and other documents that are commonly used by instrument fitters and technicians.

Coverage includes the specialized symbols used to identify lines on drawings, as well as those used to represent components and instrument locations. An introduction to the use of tag numbers for identifying instruments is included.

Course Objectives

Upon completing this P&ID Training Course successfully, participants will be able to:

- Explain and use Process Flow diagrams, P&ID’s and Instrument lists

- Specify forms, Location plans, Logic diagrams, Loop diagrams and Installation details

- Recognise process control devices and the symbols used to describe them

- Define and stipulate vendor criteria for the production of plant documentation to the order of the company

- Become familiar with the use of specifications to control the design scope of the project

- Know the purpose of a HAZOP in the development of a plant

- Be in a position to apply and manage plant modifications from conception to completion

- Become aware of the ISA standard available to support you in developing and understanding instrument and control documents

- Have a better understanding of the scope, responsibility and interaction of each discipline in the completion of a project or plant modification

- Identify and explain the types of drawings used in an instrumentation work

- Recognise and interpret instrumentation-related symbols and markings used on drawings

Training Methodology

This collaborative P&ID Training Certification Course will comprise the following training methods:

- Lectures

- Seminars and Presentations

- Group Discussions

- Assignments

- Case Studies and Functional Exercises

Zoe Talent Solution follows the ‘Do-Review-Learn-Apply’ model.

Organisational Benefits

Companies who nominate their employees to participate in this P&ID Training Course can benefit in the following ways:

- Keep your business one step ahead with this all-inclusive overview of P&ID

- Assist technical committees to create, publish and revise working standards relating to P&ID

- Carefully study examples & case studies to demonstrate the material being considered and make sure that the material is appropriate to the organisation represented

- Leave with an awareness and understanding of their roles and responsibilities in the workplace in relation to P&ID documentations

Personal Benefits

Individuals who participate in this P&ID Training Course can gain from it in the following ways:

- Understand the principle of operation of a range of sensors and transducers used in P&ID

- Review the construction and operation of P&ID

- Evaluate and select the most appropriate sensor technology for a given P&ID

- Design, build and test using a given specification of P&ID

- Identity components and features of a P&ID

- Optimise control by using relevant software of P&ID

Who Should Attend?

P&ID Training Course would be suitable for:

- Instrumentation and Control Engineers & Technicians,

- Electrical Engineers,

- Project Engineers,

- Telecommunications Engineers & Technicians,

- Process Control Engineers,

- Consulting Engineers,

- Maintenance Engineers & Technicians,

- Production Controllers,

- Project Managers,

- Electricians and Drawing Office Staff

Course Outline

MODULE 1: Instrumentation Documents

- Standards and Regulations

- Introduction to Print Reading

- Introduction

- Anatomy of a Drawing

- The Title Block

- Grid System

- Revision Block

- Changes

- Notes and Legend

MODULE 2: Instrument Drawings and Documents

- Process Block Diagram

- Process Flow Diagrams (PFD)

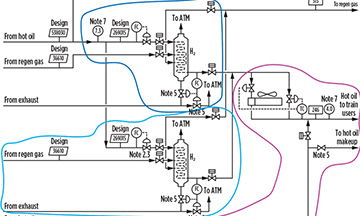

- Piping and Instrumentation Drawing (P&ID)

- Electrical Loop Drawing

- DCS I/O Loop Drawing

- Pneumatic Loop Drawing

- Cause and Effect Charts

- Functional Logic Diagram

- Instrument Installation Hook-Up Diagram

MODULE 3: Piping and Instrumentation Diagrams

- Piping and Instrumentation Diagram (P&ID)

- P&ID Symbols

- Line Numbering

- Valve Numbering

- Equipment Identification

- Abbreviations

- P&ID Examples & Uses

- SENSORS (Sensing Element): Temperature, Flow, Pressure and Level

- Valves: Valve Types, Valve Identification, Valve Fittings and Examples

- Equipment: Vessels, Pumps, Heat Exchangers, Compressors, Equipment Identification, Equipment & Instrumentation Hook-up Diagrams and Examples

MODULE 4: Interpreting P&IDs (control & safety systems)

- Distributed Control Systems (DCS)

- Safety Instrument System (SIS)

- Instrument symbols

- Instrument signal lines

- Pressure instruments

- Temperature instruments

- Flow instruments

MODULE 5: Flow Measurement

- Detailed engineering drawings

- Plot plan

- SAMA (Scientific Apparatus Makers Association) diagram and Loop Drawing interpretation

- ISA standards

- Instrumentation Symbols and Identification,

- Binary Control Logic Diagrams for Process Operations

- Graphic Symbols for Logic, Computer Systems and Distributed Control or Shared Display Instrumentation

- Instrument Loop Diagram

- Graphic Symbols for Process Displays

- ISA vs. SAMA Logic diagram

- Function block diagram

- Ladder logic diagram